With the rapid development and high intensification of the global feed breeding industry, the demand for processing and investment in soybean protein isolate powder is increasing. As the main source of plant protein, soybean meal occupies an important position in feed production and animal breeding. However, soybean meal also has the characteristics of low digestibility, many anti-nutritional factors, and weak functionality, which limit the application of soybean protein, especially in young animals.Therefore, processing soybean meal through a certain technology design to remove anti-nutritional factors while improving the digestibility of soybean foil protein and improving its functionality is an effective way to improve the fen utilization rate of soybean protein isolate.

Soybean Protein Powder Processing

Soy protein isolate powder is a nearly purified protein extracted from soybeans through a series of processing steps. Soy protein isolate contains eight essential amino acids, which are similar to meat, fish, eggs, and milk, and are full-price proteins. Studies have shown that protein is the material basis of life and one of the three major components of the human body. The lack of protein will directly lead to growth retardation, weakened immunity, loose skin and premature aging.

At present, the production of soy protein isolate powder has just started in the world, there are not many manufacturers, and the production technology needs to be improved.From the perspective of production technology and processing methods, with the help of the existing domestic equipment for the production of protein isolate by the alkaline immersion and acid precipitation method, the production technology of various manufacturers is absorbed and the appropriate production technology is adopted. It can produce qualified soybean protein concentrate products, and have better social and economic benefits.

The quality requirements of the soy protein isolate product are: uniform surface color, no hardness, full of elasticity, water and oil absorption, etc. Through several years of production practice, we have realized that in order to produce soy protein isolate that meets the above requirements, there must be strict requirements from raw materials to processing. The following are the production conditions of soy protein isolate powder for the reference of investors who want to invest in the soy protein processing industry.

Best Price Soybean Isolate Protein Powder in Kenya

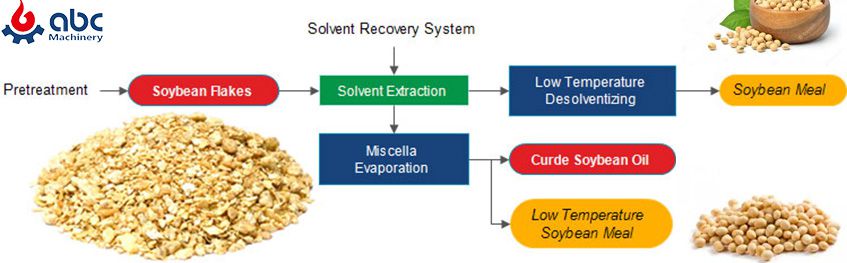

Low Temperature Bean Foil Processing Workshop

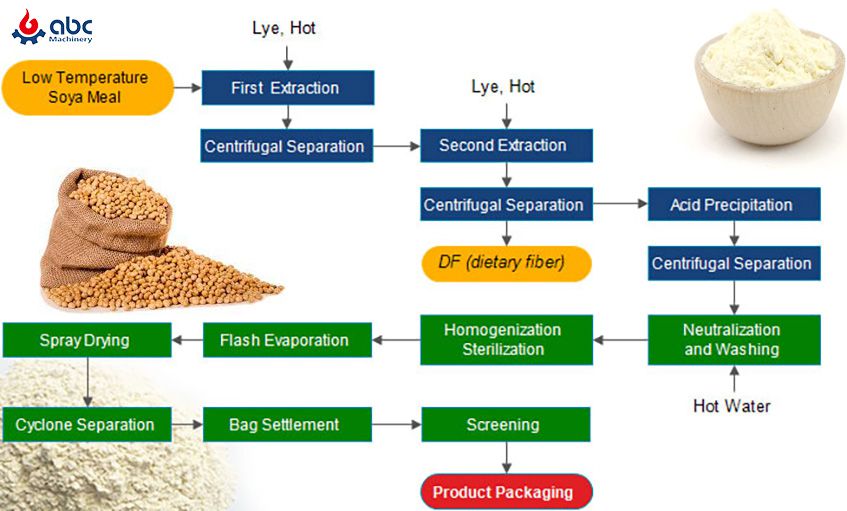

Dissolution extraction: using the dissolving properties of soybean protein, using a weakly alkaline aqueous solution (NaOH) to soak low-temperature defatted soybean meal to extract soluble proteins and low-molecular-weight sugars, and then use a centrifuge to separate insoluble fibers and solid residues;

Acid precipitation process: Use a certain amount of aqueous hydrochloric acid solution to adjust the pH value of the dissolved protein solution, and then separate the precipitated protein gel with a centrifuge;

Neutralization, homogenization, sterilization and spray drying: The separated protein is homogenized, sterilized, vacuum flashed and pressurized and then spray-dried to obtain soy protein isolate powder.

Soy Protein Isolate Processing Procedures

In summary, using the soy protein production line designed by ABC machinery to produce soy protein isolate powder has the advantage of providing a variety of nutrients to the human body, solving the problem of single nutrition in the original technology, reasonable design, advanced technology, and high degree of automation. Moreover, soy protein products have good functionality and a wide range of applications. Welcome to leave your processing needs in the message form below, we will give you a satisfactory answer as soon as possible! (Related Post:100TPD Soybean Protein Isolate Plant Project Built In Uzbekistan>>)