The fact is, as we all know, not all wheat flour milling is processed in the same way. It may vary depending on your specific requirements and the nature of the type of wheat. So, if you want to setup a small, medium or large industrial wheat flour mill plant but have no idea, most importantly and first and foremost you must have an initial understanding of the wheat flour milling process, and what wheat flour milling equipments will be used in the each process.

Wheat Flour Processing Technology Customized Design

The following is a basic milling process of wheat you can use as a reference, if you are interested in wheat flour mill business, you can consult us with your specific requirements, we will have professional engineers to do customised wheat flour production process design for you!

You may intersted: Flour mill business in Pakistan>>

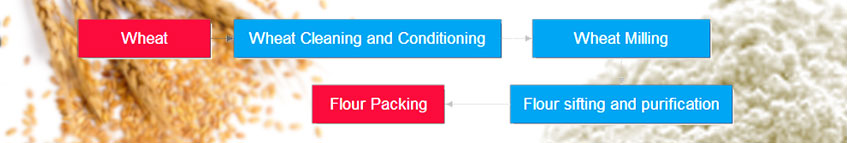

The wheat milling process is a series of steps that transforms wheat grains into flour, providing a vital ingredient used in a wide range of food products. This process involves wheat grains cleaning, wheat conditioning for optimal milling, wheat milling into flour, and wheat flour purifying to remove impurities.

Wheat Flour Milling Process Intorduction

The first step in the complete wheat milling process is the wheat cleaning stage. Wheat grains go through various grain cleaning equipment, such as vibrating screens, magnetic separators, and grain cleaners, to remove any unwanted materials such as stones, dirt, and other foreign substances. This ensures that the wheat is pure and free from impurities.

After cleaning, the wheat grains undergo conditioning, where water is added to adjust the moisture content and temperature. Conditioning makes the grains more suitable for milling and improves the quality of the resulting flour. It involves allowing the wheat grains to rest for a specific period, which can enhance the milling process and improve the flour yield.

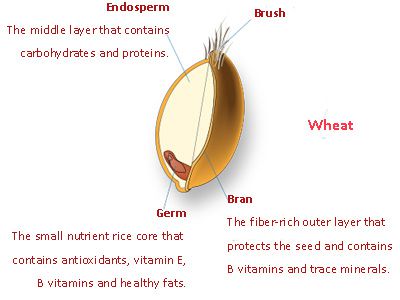

In the wheat milling processing step, the conditioned wheat grains would be milled to produce flour. The wheat grains are broken into smaller particles, separating the endosperm (starchy part), bran (outer layer), and germ (nutrient-rich part) in this processing step, where the endosperm is ground into flour to minimize the other parts.

Wheat flour milling process step involves grinding the wheat using specialized equipment like roller mills, hammer mills, or stone mills. At present, the most commonly used flour production equipment in the wheat flour industry is the roller mill. Different wheat processing steps techniques can yield various types of flour, including whole wheat flour, white flour, or specialty flours.

Following the wheat milling process stage, the flour goes through sifting and purification processes. Through the processing of bran mill, core mill, tail mill, cleaned wheat grains becomes coarse flour. After that, the loose coarse wheat flour will enter high plansifter, and the multi-layer lattices inside high plansifter with different allocation can flour into different sieving paths, ultimately realize the purposes of grading and sieving of wheat flour.

The basic flour that meets standards with different components and characters are mixed together in certain proportion to make different grades of flour. Then the flour goes magnetic separation to get rid of magnetic substances, and directly be delivered to flour packing machine for weighing and hand packing. The packaged flour is then ready to be shipped and used in various food products, such as bread, pasta, cakes, and pastries.

It's worth noting that the wheat milling process can vary depending on factors such as the desired flour quality, milling technology, and specific equipment used. Advanced milling systems may incorporate additional steps like tempering, debranning, or specialized purification processes to further enhance flour quality and meet specific market demands.

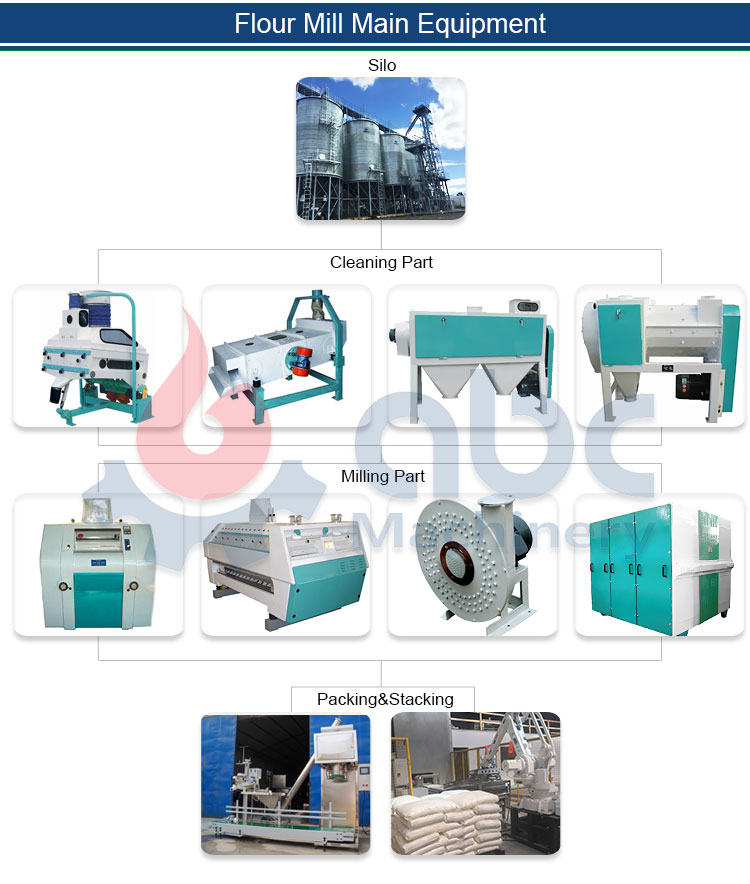

Understanding wheat flour milling equipment is essential in the food processing industry if you have an idea about starting a flour milling profitable business. In the above description of the steps in the wheat processing process, the equipment used in this step is also mentioned. The following is a list of some basic wheat flour processing machines used in the wheat milling process.

| Process | Equipment Name | Instructions |

|---|---|---|

|

Wheat Cleaning Equipment |

Vibrating screen | Remove large impurities and foreign materials |

| Magnetic separator | Remove magnetic impurities such as iron or steel particles | |

| Grain cleaner | Remove smaller impurities like dirt, stones, or broken grains | |

| Wheat Conditioning Equipment | Conditioner | Add water to adjust the moisture content and temperature of the wheat grains (tempering bins, conditioning silos, or water addition systems ) |

| Wheat Milling Equipment | Flour Roller Mill Machine | Use a series of rollers to break wheat grains and separate various components |

|

Flour Purfication Equipment |

Sifters or sieves | Equipment with perforated screens used to separate different particle sizes of flour |

| Purifier | Remove bran particles and other impurities through a combination of sieving and air aspiration | |

| Air streams/aspiration system | Remove lighter and damaged particles from the flour | |

| Flour Packaging Equipment | Automatic Flour packing machine | Pack the flour into bags of various sizes |

| Other | Storage Silo | A specialized structure designed to store and handle flour |

Of course, it is worth noting that the specific equipment used will vary depending on wheat flour manufacturing process, the size of the milling operation, the quality of flour required, and technological advances in the industry. Modern milling facilities may employ additional specialized equipment or automated systems to improve efficiency and quality control. (Related Post: Flour mill business in Nigeria>>)

Wheat Flour Processing Steps by Machines

Buy Affordable Wheat Flour Mill Machines From Reliable Manufacturer-ABC Machinery

ABC Machinery have dedicated 25 years to perfecting the art of wheat flour machinery manufacturing, project design, accessories supply, after-sales maintenance, technology consulting, staff training and all other services. We have many wheat milling plant project in many countries around the world.

Well-Made Commercial Wheat Flour Mill Machine For Sale

Related Projects:

160TPD Wheat Flour Mill Plant Built At New Zealand>>

60 TPD Wheat Flour Processing Plant Project In Algeria>>

30 TPD Wheat Flour Production Plant Project In Chile>>

.......

In fact, not all the wheat flour milling goes the same way. It may vary according to your own requirements. So, if you want a turnkey project, just feel free to contact us!