The wheat grain (clean wheat) that has gone through the cleaning process and moisture conditioning step is processed into wheat flour suitable for different needs through mechanical method. This is the wheat flour milling process. It should be noted that the important problem to be solved in flour milling is how to ensure high flour extraction rate and low wheat bran content in wheat flour.

Buy Cost-effective Wheat Grinding Machine for Your Business

Wheat grinding is the most complex and important section of wheat processing. The wheat flour making process mainly includes steps such as grinding, impacting, purification and sieving. This article mainly introduces the wheat grinding process. Other steps after grinding will be described in another article to help you succeed in your wheat flour milling plant investment.

Click to see the complete wheat flour processing process step by step>>

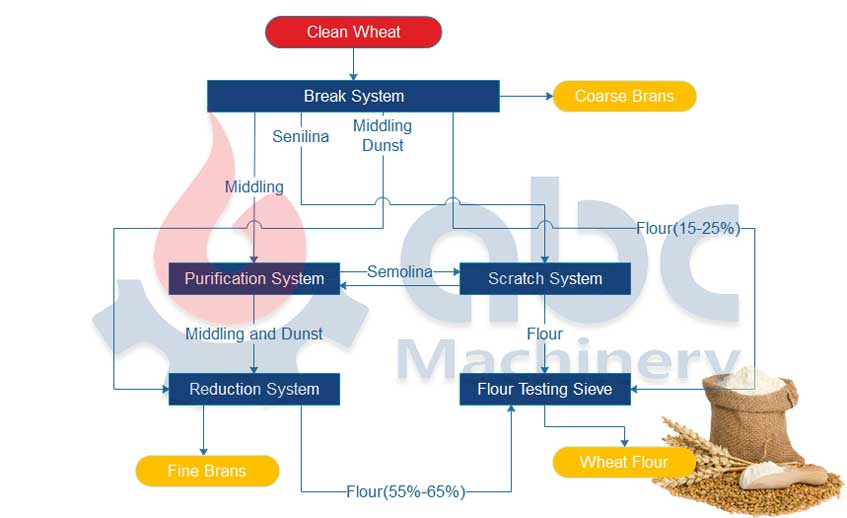

In the wheat grinding process, according to the types of materials processed by each grinding system, the flour milling system is divided into Break system (B), Scratch system (S), Purification system (P), and Reduction system (M) and Tailing system (T). They process different materials respectively and complete their different functions.

Wheat Grinding Process Flow Chart

The function of the break system is to peel the wheat grains, scrape the wheat semolina, middling and coarse flour from the bran flakes, and keep the flakes from being overly broken, so as to maximize the separation of endosperm and wheat bran and extract a small amount of wheat flour.

The scratch system is used to process the endosperm with wheat hulls separated from the break system and other systems. It provides a second opportunity to separate the wheat brans from the endosperm. After the wheat residue is separated from the wheat brans, better quality middling and dunst are produced, which are sent to the reduction system to make flour.

The function of the purification system is to use the combined action of screening and winnowing of the purifier to separate the mixture of semolina, middling, dunst and bran powder and bran chips obtained in the wheat grinding systems, and then send them to the corresponding grinding system processing.

The reduction system mills the middling and dunst obtained from Various grinding systems into wheat flour with a certain fineness.

Tailing system is located in the middle and rear section of the reduction system. It is specially designed to process the middling of lower quality containing bran debris and extract a small amount of wheat flour from it.

Explanation of professional terms

Semolina: Endosperm particles with wheat bran passed through 20W (780μm), retaining 64W (237μm).

Middling: Endosperm particle with a particle size between semolina and dunst mixed with a small amount of wheat bran.

Dunst: Coarse flour, a relatively pure endosperm particle with a particle size between semolina and dunst.

After understanding the core systems of the wheat grinding process, it is time to mention the core equipment of wheat grinding process: flour roller mill. The following will introduce the types and main structures of grinding mills, which can help you better choose grinding equipment.

The development of wheat grinding mills has gone through the development process from single type wheat flour mill machine to duplex type wheat grinders from manual control to pneumatic roller mill and electric control wheat grinding machinery, and from small to large wheat milling machine. There are the following types according to different classification methods.

| Types | Length of Roller | Diameter of Roller |

|---|---|---|

| Large wheat milling machine | 1500mm、1250mm、1000mm、800mm | 250~300mm |

| Medium wheat mill machine | 600mm、500mm、400mm | 220~250mm |

| Small wheat grinding machine | 350mm、300mm、200mm | 180~220mm |

The flour mill machine is the core equipment for wheat flour production plant. If you plan to start a wheat flour milling business, it is important to choose a professional wheat grinding machine manufacturer/supplier.

ABC Machinery's product range of flour mill machines covers a variety of models and sizes to meet the needs of different customers. Our wheat grinding machine include small M6 series and large MF series pneumatic flour mills. Each model is engineered to be efficient, reliable and durable. (See More Details: ABC's commercial grain flour milling equipment for sale>>)

No matter what the customer's needs are, our company is committed to providing high-quality, high-performance grinding mill products to create greater value and competitive advantage for customers.

ABC's flour mill plant boasts a customizable PLC control system, enabling round-the-clock fully automated operation. This innovation liberates workers from mundane tasks, granting them ample time for crucial debugging and troubleshooting.

Moreover, the PLC control system offers real-time monitoring on computer screens, empowering workers to swiftly identify and resolve any issues as they arise.

If you want to know more about wheat milling knowledge, or are interested in ABC's flour milling equipment, please contact us!