Maize, which is also known as corn, is one of the most widely planted grains in the world, and it can be processed into maize flour, maize grits, or even maize starch. The production of maize involves a series of steps that include various types of maize milling machinery for cleaning and grinding the maize kernels. This process can be automated to reduce labor costs, energy consumption, and ensure the quality of the final products.

In this column, from corn starch to corn grits and corn flour, we will cover the entire process and provide insights to help farmers, small- and large-scale millers, and food manufacturers optimize their maize processing techniques. Make sure to explore our other articles in this column to deepen your understanding of maize processing.

There are several methods used to process maize flour, including:

Dry Milling: This is the most common method used to process maize flour. In this method, the maize kernels are cleaned and then ground into a fine powder using a hammer mill or a roller mill. The resulting flour is then sifted to remove any large particles or impurities.

Wet Milling: This method is used to produce a finer quality maize flour. The maize kernels are first soaked in water for a period of time to soften them. They are then ground into a slurry using a wet mill, which separates the various components of the kernel. The resulting mixture is then dried and ground into a fine flour

Stone Grinding: This traditional method of maize flour processing involves using a large stone to grind the maize kernels into flour. This method is still used in some parts of the world, particularly in rural areas where modern equipment is not readily available.

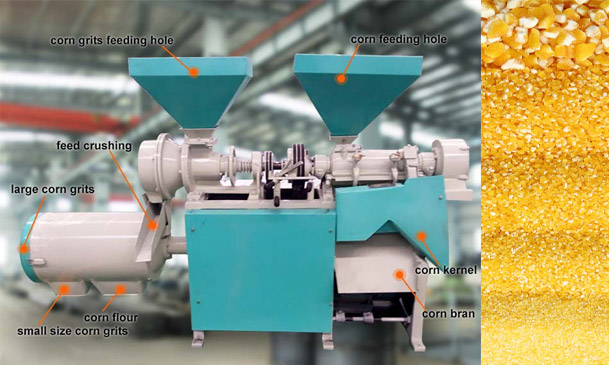

Industrial Processing: In large-scale maize flour production, industrial processing methods are used. This involves using advanced milling and sifting equipment to produce high-quality maize flour. The process includes cleaning, conditioning, de-germinating, milling, sifting, and packaging.

Maize milling has undergone significant technological advancements in recent years, allowing for improved efficiency and higher quality end-products. One such innovation is the use of digital sorting technology, which allows for the precise sorting of maize kernels based on various factors such as size, color, and shape. This ensures that only the highest quality kernels are used in processing, resulting in superior end-products. Additionally, advancements in corn milling technology, such as the use of degerminators and roller mills, have improved the efficiency of maize milling, reduced waste and increasing yields. These innovative technologies have not only improved the quality and efficiency of maize processing but also offer a competitive advantage for companies in the market.

ABC Machinery is committed to offering comprehensive engineering and construction services to clients worldwide. Our highly skilled team possesses extensive knowledge and experience in maize processing and can deliver tailored solutions to suit your unique requirements. As a farmer, small- or large-scale miller, or food manufacturer, you can rely on our expertise and resources to streamline your maize processing operations and succeed in this burgeoning industry.