Corn Milling Business Opportunities in Developing Countries

Global demand for maize-based products is expanding rapidly, driving the need for modern corn mill facilities across Africa and Asia. In Ghana alone, per capita corn flour consumption has increased by 28% between 2018 and 2024, while Nigeria’s market is valued at over USD 1.3 billion annually. India and the Philippines, with combined populations exceeding 1.5 billion, are witnessing rising urban demand for affordable corn flour as a staple and industrial ingredient. (Related Post: Start Mazie Mill Business in South Africa>>)

The corn milling market in Ghana has become a strong magnet for agro-industrial investors due to import substitution policies and subsidies that reduce grain import dependence. Similar initiatives are evident in Kenya and the Philippines, where local governments support corn processing as part of national food security programs.

Government-backed financing and tax incentives are key enablers in these regions. For example, Ghana’s 1D1F (“One District, One Factory”) policy grants up to 30% capital support for agro-processing plants, while India offers 5-year tax holidays for new rural food-processing units.

Partner with our engineering experts to identify the right investment region and design your high-efficiency corn milling business setup today.

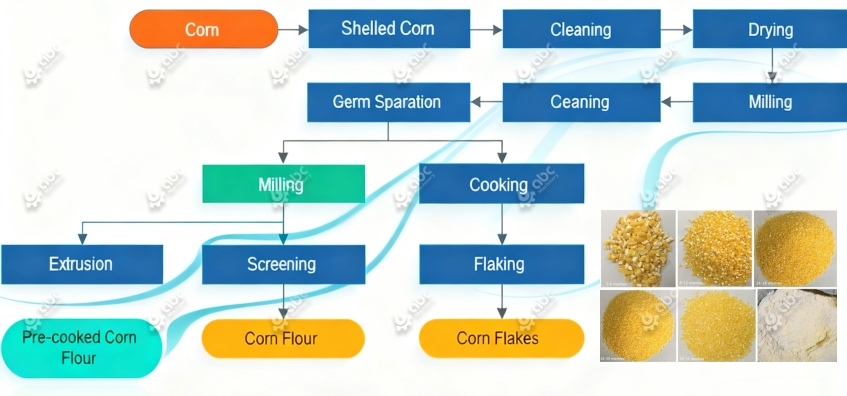

Simple Corn Milling Process Flow Chart

Efficient design and engineering are the foundations of a successful corn milling business. A well-structured corn milling plant design optimizes material flow, minimizes energy loss, and supports consistent flour quality across multiple production lines. Typical industrial plants range from 30 to 200 tons per day (TPD) capacity.

A modern industrial corn mill process flow involves several core systems:

Each step contributes to yield improvement and power efficiency. For instance, using air-recycling aspiration systems can save up to 15 kWh per ton, while advanced roller mills achieve 95% germ removal efficiency.

| Process Section | Key Equipment | Typical Capacity (TPD) | Power Requirement (kWh/ton) |

|---|---|---|---|

| Cleaning & Conditioning | Vibrating separator, destoner | 30–150 | 7–10 |

| De-germination | Degerminator, aspirator | 30–200 | 10–15 |

| Milling & Sifting | Roller mill, plansifter | 30–200 | 20–25 |

| Packaging & Storage | Automatic bagging, silos | 30–200 | 5–8 |

Automation plays a central role in next-generation corn mills. Integrating PLC (Programmable Logic Controller) systems and SCADA (Supervisory Control and Data Acquisition) allows real-time process control, error detection, and production traceability. Plants equipped with NIR (Near-Infrared Reflectance) moisture sensors reduce process variation by 8–12%, improving yield consistency and minimizing energy waste.

Proper layout planning minimizes material handling distance and reduces total operation cost by up to 10%. Energy-efficient fans and variable-frequency drives (VFDs) are now standard for optimizing throughput and extending equipment life.

Corn Flour Mill Plant Equipment Layout by Production Process

Get your customized corn milling plant layout and process optimization blueprint – contact our engineering team now.

Building a corn milling plant investment cost model helps investors evaluate expected returns and financial sustainability. A mid-sized 100 TPD plant typically requires USD 800,000–1.2 million in capital investment, including machinery, civil works, and installation. Operating expenses—comprising raw maize (65%), power (15%), and labor (10%)—represent the largest cost categories.

Average corn flour factory ROI analysis in Africa and Asia shows 20–28% annual return rates, with a payback period of 3–4 years. Cost optimization through local equipment sourcing and efficient energy design can increase margins by 5–7%.

Start Small to Medium Scale Maize Flour Mills Business in Africa

Successful execution of a corn mill project installation requires clear planning and integrated engineering control. Typical project timelines range from 6 to 9 months for complete commissioning. Installation includes civil foundation work, mechanical assembly, electrical wiring, and automation programming. Advanced SCADA-based systems streamline commissioning by synchronizing power, motor load, and process control.

Automation commissioning in a milling plant ensures stable production and quality. Post-installation, training programs for local technicians cover preventive maintenance cycles every 1,000 operational hours and calibration procedures for NIR sensors.

Connect with our engineering implementation team to achieve on-time plant commissioning and sustainable production performance.

In conclusion, investing in a modern corn mill facility across Ghana, India, or the Philippines offers strong returns, scalability, and long-term food security alignment. By focusing on engineering precision, automation, and cost optimization, your corn milling business can become a profitable industrial operation serving growing domestic and export markets.