Step-By-Step Flour Mill Startup Guide in Pakistan

Pakistan is among the world’s top ten wheat producers, with an annual yield exceeding 27 million tons in 2024. The demand for processed flour continues to rise by 5–7% per year, driven by population growth and increasing consumption of bakery and confectionery products. Launching a flour mill in Pakistan offers strong potential for investors and engineers alike.

Pakistan’s flour market is valued at approximately USD 4.5 billion, with over 1,000 operational mills nationwide. Urbanization and the expansion of packaged food sectors are fueling additional processing capacity. According to the Pakistan Bureau of Statistics, average per capita wheat consumption remains around 125 kg per year, ensuring stable domestic demand. Government incentives under the Agro-Processing Development Policy 2023 also encourage industrial flour processing projects.

The flour milling sector’s efficiency varies across regions — Punjab alone accounts for nearly 60% of wheat milling capacity. Establishing new mills in Sindh or Khyber Pakhtunkhwa can yield competitive advantages due to lower land prices (USD 20–25/m²) and untapped market access.

Entrepreneurs looking to start a flour mill business in Pakistan can benefit from export facilitation measures, including duty-free import of advanced milling equipment and concessional financing from the State Bank of Pakistan’s Long-Term Financing Facility (LTFF). With a capital investment range between USD 1.5–3 million for a medium-sized plant, returns typically materialize within 3–5 years under efficient operation.

Pakistan’s flour processing landscape offers scalable opportunities for investors adopting energy-efficient and automation-driven technologies.

Small Flour Production Line for Home Use / Farmers

Partner with our industrial engineering team to design your high-performance flour milling facility in Pakistan today.

Building a flour mill in Pakistan requires careful planning, beginning with location selection and extending to process optimization. Proper engineering layout can boost productivity by up to 20%, while minimizing energy loss and material waste.

Selecting a flour mill plant site involves assessing access to raw materials, utilities, and distribution routes. Ideally, the site should be within 50 km of major wheat supply areas and connected to highways or railway networks. Land requirements vary between 10,000–15,000 m² for a 200-ton/day capacity mill.

Plant capacity must align with regional demand projections. A typical 200 TPD (tons per day) mill requires:

| Section | Key Equipment | Area Requirement (m²) | Energy Load (kW) |

|---|---|---|---|

| Cleaning | Destoner, Scourer | 40 | 75 |

| Milling | Roller Mills, Purifiers | 120 | 160 |

| Packing | Bagging Machines | 60 | 30 |

Large Modern Flour Mill Processing Zone

When designing the flour mill plant layout, engineers should integrate process flow from raw wheat intake to flour dispatch with minimal material handling. Using CAD-based layout tools and Manufacturing Execution Systems (MES) can optimize operations and reduce downtime by 10–15%.

Proper zoning reduces cross-contamination and improves compliance with ISO 22000 food safety standards.

Get Your Customized Flour Factory Design Blueprint – Contact Our Engineering Team Now.

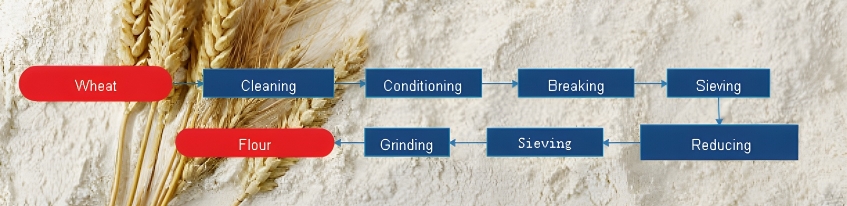

Simple Wheat Flour Production Process Flow

The wheat flour milling process typically follows three stages: wheat cleaning, conditioning, and grinding. Selecting the right flour production machinery is critical for product quality and efficiency.

Modern automated flour mills integrate PLC-controlled (Programmable Logic Controller) systems for monitoring throughput and product consistency. Machines like the plansifter, roller mill, and purifier help achieve flour extraction rates above 75% with uniform granulation.

Quality control involves NIR (Near-Infrared Reflectance) technology to assess protein and moisture levels. Energy-efficient designs can lower power consumption to 70–80 kWh per ton of flour produced.

Connect with our process engineers to optimize your flour milling line for automation and quality consistency.

Building a flour mill in Pakistan involves both fixed and variable costs. Capital expenditure for a 200 TPD plant typically ranges from USD 1.8–2.5 million, covering civil works, equipment, and utilities. Operating expenses primarily include energy (25%), raw wheat (60%), and labor (8%). (Related Post: Flour Mill Plant Cost in Pakistan>>)

| Category | Cost Share (%) | Typical Range (USD) |

|---|---|---|

| Machinery & Installation | 35 | 700,000–900,000 |

| Civil Construction | 25 | 450,000–600,000 |

| Electrical & Utilities | 15 | 250,000–350,000 |

| Working Capital | 25 | 400,000–500,000 |

Energy efficiency is a critical cost factor — using variable frequency drives (VFDs) can save up to **15% electricity**. With optimized plant management, payback periods typically fall between **3.5–4 years**, offering steady returns through high utilization rates and regional distribution.

Continuous monitoring of production yields and downtime minimizes waste and enhances profitability.

Consult our industrial analysts to structure your flour mill investment plan for faster ROI and sustainable growth.

Flour mill in pakistan remains a promising industrial segment for investors aiming to modernize the country’s food production infrastructure. A well-engineered setup ensures consistent output, cost efficiency, and long-term competitiveness for those entering the milling industry.