ABC Machinery provides turnkey project design for soy protein isolate production process with the aim to produce higher quality soy protein isolates and lower the investment cost. If you are planning to start soy protein isolate manufacturing plant, it is necessary to have a deep understanding about how is soybean protein isolate processed. Welcome to contact to get latest project report!

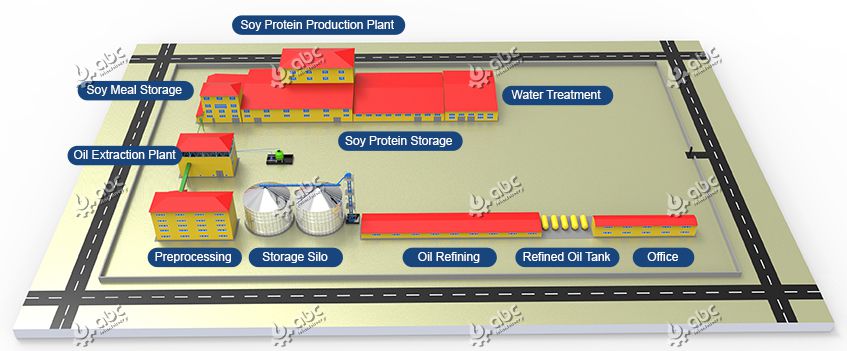

The 100TPD Soy Protein Isolate Production Project undertaken by ABC Machinery is mainly designed with 5 main production sections. The raw material is Non-GMO soybean material and its annual capacity can be up to produce 6,500 tons of SPI.

Soy Protein Isolate Production Project

This design of this soy protein isolate production project makes use of the alkali dissolution and acid precipitation to separate the fiber and protein in the low-temperature soybean meal. This protein content in the final soy protein isolate is high by this technology. But, it should be equipped with water treatment facility to ensure water consumption.

Soybeans Pretreatment Factory

Low Temperature Soy Meal Extraction Plant

Soy Protein Isolate Production Plant

If you are interested in this soy protein isolate manufacturing plant and its core technical parameters and indicators, please send us massage, our professional engineers will answer enquiries over email, phone, what’s app, etc.

How is soybean protein isolate processed? This is a question that beset many investors who are interested in soy protein isolate industry. Here we provide the full soy protein isolate production process that involves soybean pretreatment, soy protein extraction, acid precipitation, neutralization, homogeneity, sterilization and flash, drying and etc. (Read more: )

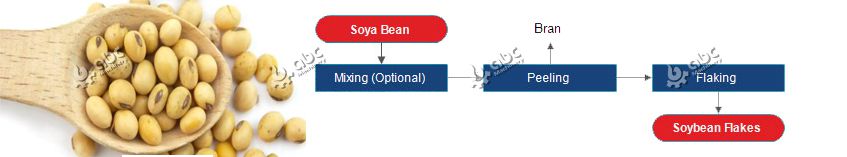

Soybeans Pretreatment Process

The soybeans pretreatment process includes cleaning, conditioning, peeling, softening and flaking. This process is to remove impurities, hulls and better prepare the soybeans for soybean meal extraction. (Read more: Beans Peeling Equipment >>)

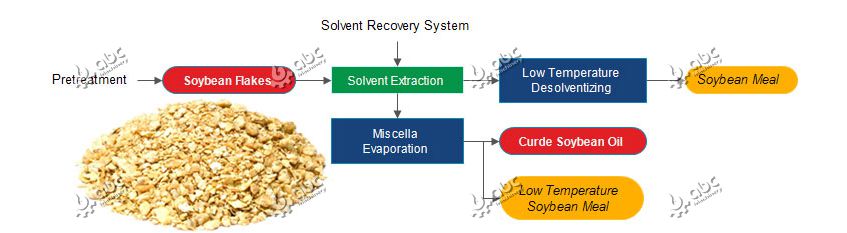

Low Temperature Soybean Meal Extraction Process

This process includes low temperature soybean meal extraction, desolvation, evaporation, solvent recovery process and more. After this process, the low temperature soybean meal is produced.

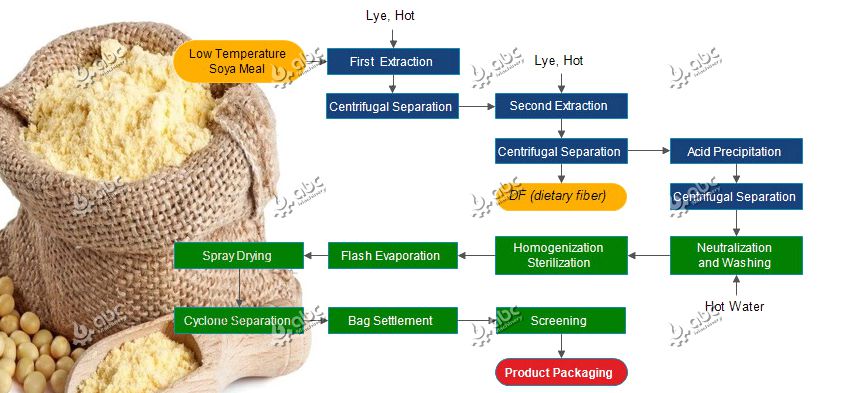

Soy Protein Isolates Production Process

This is the last process in a soy protein isolates production plant. It mainly includes dissolving extraction, acid precipitation, neutralization, homogenization, flash evaporation, spray drying, cyclone separation and more. Then, high quality soy protein isolates are produced and ready for sale.

| Item | Index | Item | Index |

|---|---|---|---|

| Protein | ≥90% (on dry basis) | Moisture | ≤7.0% |

| Fat | ≤1% | NSI | ≥85% |

| Ash | ≤6.0% | PH | 7.2±0.2 |

| Water and Oil Absorption | 1:4:4 | Fineness | ≥95% (100 mesh sieve material) |

| Total Number of Bacteria | ≤30000 per gram (pathogenic bacteria must not be detected) | ||