Kenya’s flour mill industry stands on the backbone of maize, a staple that forms the daily diet of more than 80% of households. With annual maize consumption surpassing 4 million metric tons and urbanization advancing at nearly 4% per year, the appetite for processed and packaged maize flour is steadily expanding. This shift is driven not only by population growth but also by rising demand for fortified and convenience-oriented products in both urban and rural markets.

In this context, understanding the landscape of maize flour mill machine options, optimizing maize milling processes, and analyzing market trends are no longer technical decisions alone—they are strategic moves that define profitability and competitiveness.

Purchase Cost-effective Maize Four Milling Machine From ABC Machinery

This article explores Kenya’s maize milling equipment types and selection principles, outlines best practices in production and quality control, and highlights market trends with actionable insights for investors.

The growth in urban populations, coupled with rising demand for packaged and fortified maize flour, is pushing maize millers to invest in advanced maize flour mill machine solutions that improve efficiency and product consistency.

Small-scale maize mill machines (1–5 tons/hour) suit local traders and small cooperatives, costing around USD 3,000–8,000. Medium-capacity flour mill plant (10–20 tons/hour) cater to regional distributors and cost between USD 25,000–60,000. Large-scale automatic corn flour milling systems, exceeding 50 tons/hour, are used by leading brands, with investments starting from USD 150,000.

Low Cost Mini, Small, Large Maize Flour Mill Plant For Sale

Adopting automatic maize milling equipment can reduce labor requirements by 30–40% and improve throughput by up to 25%. Energy-efficient models, often incorporating regenerative braking and optimized motor control, can save 12–18% on power costs annually.

You may interested in: Maize Mill Plant Business Cost in Kenya>>

Proper maintenance scheduling, including weekly inspections and quarterly overhauls, can extend equipment lifespan from 10 to 15 years. Access to local spare parts suppliers in Kenya can reduce downtime by 15–20%.

Selecting the right capacity and automation level ensures operational stability while maximizing return on investment.

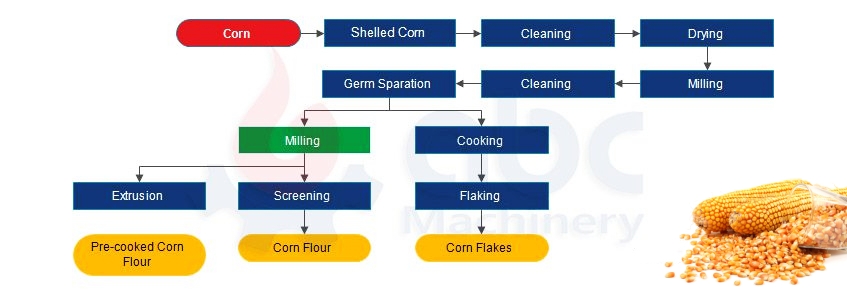

In Kenya, the maize flour milling process typically includes several critical stages: cleaning, dehulling, milling, sifting, and packaging. Each step directly influences the final product’s quality, yield, and safety, ensuring that the flour meets both consumer expectations and regulatory standards.

Corn Flour Milling Process Steps Details

Read More: Maize Grits Processing>>; Maize Starch Processing>>.

Quality Control Measures

Strict adherence to Kenyan Bureau of Standards (KEBS) ensures products meet national safety, labeling, and quality benchmarks, facilitating market access and consumer trust.

Start your maize flour milling investment in Kenya – Secure your market share today!

Kenya’s maize flour market is valued at over USD 1 billion annually, with per capita consumption exceeding 90 kg/year. Urban demand for fortified flour is growing at 6–8% per year, while rural areas still prefer unfortified meal for traditional recipes.

Leading brands like Unga Group, Pembe Flour Mills, and Mombasa Maize Millers dominate urban supermarkets, while hundreds of smaller millers serve rural communities.

Setting up a 20-ton/day maize flour mill requires USD 50,000–70,000 in equipment and facilities, with an expected payback period of 3–4 years. Key risks include maize price volatility and seasonal supply shortages, which can be mitigated through supplier contracts and diversified sourcing. Entering now allows investors to capture growth in the fortified flour segment before market saturation.