Flour sifting is an extremely important process in wheat milling, the purpose of which is to classify the mixture of intermediate products from the wheat mill process by size and, to some extent, by quality.

Click to see the complete wheat flour processing process step by step>>

As we have mentioned elsewhere in this column, the milling step in a flour mill plant consists of several different grinding systems. And the different particle sizes from these systems are sorted through the flour sieving step so that they flow to the corresponding subsequent processing systems.

Understanding Wheat Flour Sifting Process for Excellent Production

In the processing of grains such as wheat or corn, the sifting and grading process affects the quality, purity and suitability of the final flour product. Reducing bran impurities and improving flour particle uniformity. As consumer demand for hygienic safety and quality of wheat flour continues to increase, screening process is critical to sustainable wheat flour mill plant operations.

Contact the leading provider of wheat flour mill project solutions, ABC Machinery, for expert technical support and cost-effective processing equipment!

Flour sifting and grading is an important process in the production of high quality flour and the following section focuses on how this process is carried out and the specialized flour sifting machine used.

According to the requirements of the wheat flour making process, the milled intermediate products are divided into four categories according to particle size: bran flakes, coarse grains, coarse meal and flour.

In the sifting process, the material is sent to the appropriate grinding or purification system for further processing according to the principle of "homogenization", while the material that has reached flour fineness is collected.

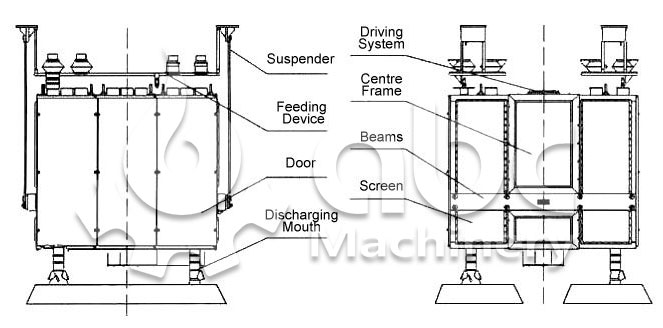

Main Flour Sifting Machine-High Square Plansifter And Internal Seive Frame

During the sieving process, the raw material is moved by vibration or rotation in the sieving equipment. Depending on the aperture size of the screen, smaller particles pass through the screen while larger particles are blocked on the screen surface.

It is important to note that the operation of the sifting equipment needs to be continuously monitored throughout the process and adjusted as needed. Parameters such as vibration amplitude, screen cleanliness, or screen hole size may need to be adjusted to ensure that the screening results are as expected.

Typically, since each set of screen surfaces can only be separated into two categories, screen tops and screen bottoms. n-1 sets of screen surfaces are utilized within the same flour sifting machine when the intermediate product needs to be separated into n grades.

Wheat processing plant commonly used equipment is plansifter, commonly including high square plan sifter, double section plansifter and so on. Double section flat sieve is small, the number of layers of the sieve frame is small, fewer types of grading, mostly used for small flour milling units and flour inspection sieve. Currently widely used sifting equipment is high square plansifter.

Flour Sifting System In The 160TPD Large Wheat Milling Plant

ABC Machinery's high square plan sifter are available in various sizes to meet the needs of small and large flour milling factory, which is suitable for wheat and corn flour mills for all kinds of grains. The following are the design highlights of our high square plansifter.

Durable Poly-V drive belt and bearing assemblies are utilized, reducing lubrication requirements and extending maintenance intervals.

The modular design allows customers to adjust the number of sections as needed or add more sections at any time. With1, 2, 4, 6, 8 or 10 sifting sections are available.

Insulation on the interior walls and doors prevents flour condensation. Key components are made of stainless steel and polyurethane with no bolt fasteners for easy cleaning. Secondly, the automatic compression system of the sieve frame keeps it sealed and prevents cross-contamination.

Want to learn more about ABC Machinery's products and services as well as current promotions? Visit our official website or click below to contact our sales team directly. Together, let us help you realize productivity gains and quality assurance!

In flour mill plants, the sifting process depends on a variety of factors, such as the route of material flow (sieve path), sieving time, the size and fit of the sieve mesh, the material load on the sieve, and various other details.

In order to ensure stable and high-quality screening effect, flour sifting process and flour sifting machine need to meet the following requirements as far as possible.