With the acceleration of urbanization in India and the upgrading of residents’ dietary structure, the small flour mill is becoming an important player in regional markets. Facing the growing demand for flour consumption and the market gap between traditional home grain milling and large industrial flour mill plant production, many investors and small business owners are seeking reliable and economical factory setup solutions.

Build Low Cost Small Flour Mill in India

This article combines practical operational experience to break down the site selection, equipment configuration selection, production process optimization, and cost-profit analysis of a small flour mill plant, offering practical suggestions to help you reduce investment risks and improve efficiency.

According to the National Statistical Office of India, urban residents’ annual flour consumption has grown by about 6–8% on average over the past five years. However, the number of local small flour mills remains limited, and many households and small vendors still rely on scattered supply or self-made flour. This mismatch between supply and demand creates opportunities for new investors.

In many rural and semi-urban areas, families still use stone flour mills or small flour milling machines to process wheat and maize themselves, but production is low and flour quality is inconsistent. On the other hand, large industrial mills have high capacity but are restricted by logistics and distribution networks, making it hard to meet regional, customized, or small-packaging needs. This “double gap” allows small flour mills to enter the market with flexible production, fast delivery, and differentiated products.

Small flour mills often face insufficient raw material procurement volume, large price fluctuations, and high storage costs. For example, wheat prices are affected by the international market and seasonal harvests, with fluctuations reaching 10–15%. In addition, poor transportation infrastructure in rural areas increases logistics costs and raw material loss risk. Without reasonable storage and distribution planning, both production efficiency and profit margins will be directly affected.

Building an efficient small flour mill plant requires more than just choosing the right location and premises. Scientific equipment configuration and optimized production processes are also essential to remain profitable in a competitive market.

Buy Small Commercial Flour Mill Machines at Low Cost

Location directly affects raw material supply, logistics costs, and sales efficiency. Urban outskirts close to consumption markets can respond quickly to orders but come with higher rent and stricter approvals.Rural areas or grain distribution hubs near wheat-producing regions offer lower procurement costs and stable raw supply but higher finished product delivery costs and require labor training.

For a small flour processing plant producing 5–20 tons/day, a net workshop area of 300–600 m² is recommended. Layout should follow the sequence: raw material warehouse near unloading area → production zone in process order → finished goods warehouse near loading area, while ensuring good ventilation, dust control, and 20–30% expansion space for future upgrades.

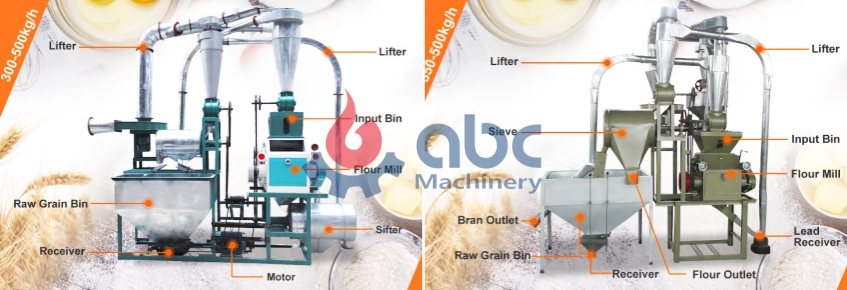

The heart of a small flour production line lies in the wheat milling machine and its capacity matching. Common small milling machines in the market have capacities from 10 to 40 TPD, and investors can choose single units or combined setups based on target daily output. Auxiliary equipment such as cleaners, sifters, and packing machines can improve flour quality and production efficiency. (Related Reading: Learning Commercial Flour Mill Machine Price in India>>)

For cost-limited setups, second-hand flour milling equipment or modular configurations can be considered, but machine condition and maintenance convenience must be ensured.

The flour production process should form a closed loop from raw material intake to finished product output.

A typical flour mill process flow includes: raw material storage → cleaning → grinding → sifting → packing.

Dust and humidity must be controlled, and safety ensured — for example, using local exhaust ventilation in the milling area and keeping humidity at 12–14% to prevent clumping. Quality control can be achieved with simple tools such as moisture meters and sieves to ensure product consistency. Developing Standard Operating Procedures (SOPs) and regularly training workers are key to maintaining efficiency and quality.

ABC Machinery Mini Flour Mill Models for Home Use for Sale

Initial investment mainly includes equipment purchase, raw material procurement, and labor costs, for example:

| Item | Reference Cost (USD) |

|---|---|

| Small milling machine (3–5 tons/hour) | 8,000–15,000 |

| Auxiliary equipment (cleaning, sifting, packing) | 5,000–10,000 |

| Factory rental & renovation | 3,000–8,000 |

| Initial raw material stock | 2,000–4,000 |

| Labor & training | 1,500–3,000 |

| Total | 19,500–40,000 |

Daily operating costs — electricity, water, transport, and raw material replenishment — account for around 30–40% of monthly sales revenue. With proper pricing and sales strategies, a 10-ton/day small flour mill can generally break even within 2–3 years. Investors should assess raw material price fluctuation and market price risks, and consider long-term supply contracts or joint purchasing mechanisms.

Before starting construction, complete location research, equipment matching, and process simulation, and perform ROI calculations. If you want a complete small flour mill setup plan — including site selection, equipment list, and cost analysis — we can provide customized consulting and on-site support to help you launch your business quickly.

Case 1: 10-Ton/Day Wheat Flour Mill Plant in a Northern Small City

This small flour mill leveraged its proximity to wheat-producing areas to establish a stable raw material supply chain and quickly penetrated local retail and foodservice channels. By standardizing production processes and applying basic quality checks, the plant ensured consistent flour quality while reducing waste and return risks, achieving steady profitability.

Case 2: Specialty Flour Mill in the South

Targeting the health and bakery market, this plant produces whole wheat flour, corn flour, and mixed grain flours. Its small-batch production model, combined with premium packaging, allowed it to create differentiated competition in the regional market. Product unit prices are 15–25% higher than regular flour, significantly boosting profit margins.

Key Takeaways

Investors can refer to the above cases to flexibly combine location, equipment configuration, and product positioning. If you want a complete investment plan and regional market analysis, we can provide customized consulting to help you quickly launch your small flour mill project.