Thinking about starting or upgrading a corn mill plant but unsure where to begin? This section offers practical guidance on every stage of corn milling plant development — from investment planning, site selection, and plant layout design to machinery configuration and cost optimization. Whether you’re building a small mill for local markets or an industrial-scale factory, you’ll find actionable insights and proven engineering approaches here.

Keep reading to explore the articles below for detailed project ideas and technical solutions.

The corn milling industry continues to experience rapid global expansion, with the market projected to surpass USD 38 billion by 2030, growing at a CAGR of around 4.5% from 2024. The increasing demand for corn-based food ingredients, biofuels, and industrial starch drives this steady growth. In 2023 alone, global corn flour consumption reached over 26 million tons, primarily concentrated in Asia, Africa, and Latin America. (Learn More about Global Flour Mill Industry Country by Country>>)

In North America, large-scale industrial corn mills operate at capacities exceeding 500 tons per day (TPD), while developing regions see an increase in small and mid-sized mills between 20–150 TPD. Such scalability makes corn milling highly attractive for factory investors and engineering consultants seeking sustainable and regionally adaptable business opportunities.

The rising trend toward food security and value-added agricultural exports positions corn milling as a critical industrial investment in emerging economies. Governments in countries like Nigeria, Ethiopia, and Indonesia are actively supporting private corn mill projects through tax incentives and subsidized energy programs.

Global competition remains moderate, with key players focusing on automation, energy optimization, and integrated processing lines. For investors evaluating entry into this profitable market, partnering with a specialized engineering provider ensures optimized factory design and long-term operational efficiency.

Building a complete corn mill requires systematic planning—from location analysis to equipment selection and workflow integration. A well-engineered setup ensures production efficiency, consistent flour quality, and minimized energy consumption.

Selecting the right location determines 30–40% of the project’s success. The ideal site should have:

A feasibility study should evaluate land cost, raw material proximity, and infrastructure access before final investment decisions.

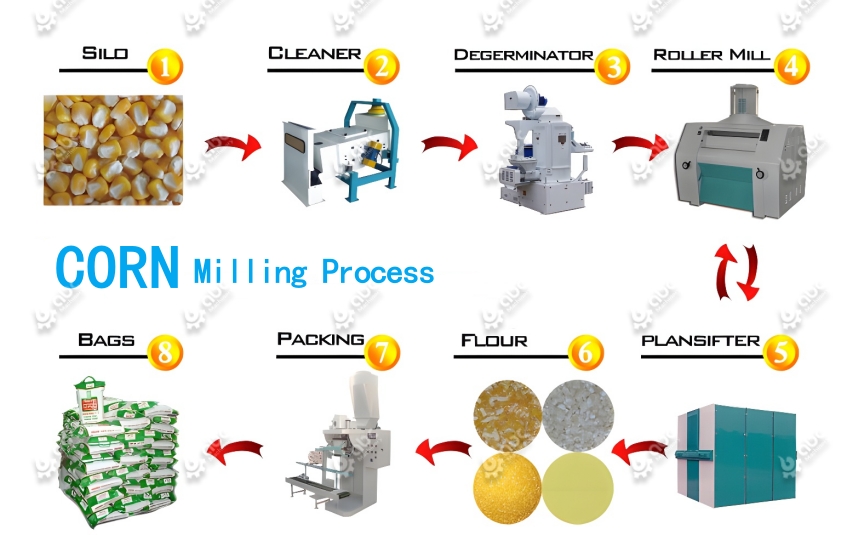

Efficient corn mill layout design maximizes production flow and minimizes material handling time. Typical facilities follow a vertical structure: cleaning → conditioning → degermination → milling → sifting → packaging.

Corn Milling Process - Processing Machines

| Section | Equipment Installed | Typical Capacity | Notes |

|---|---|---|---|

| Cleaning & Conditioning | Vibrating screen, destoner, dryer | 5–50 TPH | Removes impurities and moisture control |

| Degermination & Grinding | Degerminator, roller mill | 1–25 TPH | Determines flour quality and yield |

| Sifting & Packaging | Plan sifter, automatic packer | 500–1000 bags/hour | Automates final packaging and weighing |

Proper zoning between wet and dry sections is essential to maintain hygiene and operational safety. Automation integration with PLC systems enables real-time data control, reducing downtime by 15–20%.

Choosing the right corn mill machine defines the plant’s productivity. Reliable systems from international suppliers ensure:

Modern corn mill automation allows centralized supervision of temperature, vibration, and feed rate, leading to better flour consistency and lower waste rates. This digital integration ensures consistent quality even at 200+ TPD capacity levels.

Advanced automation systems cut labor demand by 25–35% and improve energy efficiency by 12%. Remote diagnostics help prevent unplanned shutdowns and ensure continuous operation.

Get a fully engineered corn mill plant design tailored to your capacity goals and energy efficiency targets—consult our experts for your turnkey setup plan today.

Packing and PLC System in the Automatic Corn Flour Mill Plant

Establishing a corn processing plant involves diverse cost categories. Typically, total investment for a 100 TPD mill ranges from USD 1.8–2.5 million, depending on automation level, location, and equipment origin.

In developing regions, total project costs can be reduced by 15–20% through local fabrication of supporting structures, while maintaining international performance standards through imported critical machinery.

ROI analysis indicates that modern corn mills achieve payback within 2.5–3 years, with gross profit margins of 25–30%. Secure a detailed cost assessment and project financial model—our engineering team can develop an optimized budget structure for your investment.

Running a corn mill efficiently requires balancing automation, maintenance, and energy systems. Modern facilities consume around 65–80 kWh per ton of output, making energy optimization essential.

Upgrading to variable frequency drives (VFDs) for conveyors and fans saves up to 10% in power. PLC-controlled systems synchronize feeding and grinding speeds, ensuring steady throughput. Regular calibration of weighing and dosing systems maintains yield accuracy within ±1%.

Automatic corn flour packaging lines process up to 800 bags/hour, minimizing manual handling. Storage silos must be ventilated and moisture-controlled below 13% to prevent spoilage.

Proper supplier selection for spare parts ensures operational continuity, reducing downtime costs by 12–15%.

Enhance your factory’s performance and sustainability—connect with our engineering team to develop an energy-smart corn milling solution today.