The flour mill industry in Pakistan is expanding steadily, driven by a growing population and rising demand for processed wheat products. Annual wheat consumption now exceeds 25 million metric tons, and urbanization continues to accelerate. For investors, this means a timely opportunity to set up a flour mill plant in Pakistan that not only fulfills domestic demand but can also tap into export potential in neighboring markets.

ABC Machinery Help You Setting up A Flour Mill in Pakistan

This guide focuses on three critical areas for launching a successful flour milling venture: understanding the complete flour mill plant cost, designing a productive and energy-efficient facility, and projecting profitability with realistic payback timelines. By following proven benchmarks and strategic design choices, well-planned projects often outperform the market by 10–15% in profit margins — a strong reason to explore this investment path seriously. Contact us for more information about starting a profitable business.

Starting a flour mill plant in Pakistan involves a multi-layered investment strategy balancing land acquisition, construction, equipment, and operational capital. The total flour mill plant cost can range from USD 150,000 to over USD 800,000 depending on production capacity and automation level.

Securing industrial land typically costs USD 5–15 per square foot in rural areas and USD 20–40 per square foot in urban industrial zones. An automatic 120–150 tons/day flour mill plant usually requires 20,000–30,000 square feet, translating into a land cost between USD 100,000 and USD 900,000 depending on location. Factory construction averages USD 25–35 per square foot, meaning a 25,000 square-foot facility could cost USD 625,000–875,000.

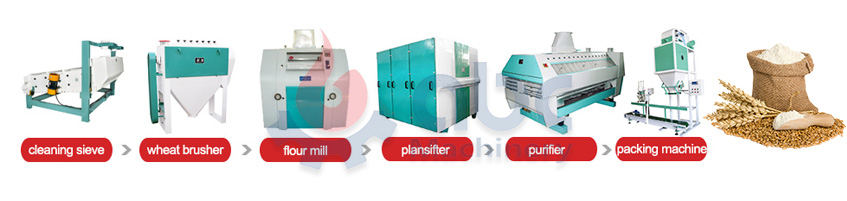

Core machinery in grain mill plant includes wheat cleaning systems, roller mills, sifters, and packaging lines. The wheat milling machine price in Pakistan ranges from USD 8,000 for small-scale units to over USD 60,000 for high-capacity roller flour mills. Installation and commissioning usually add 8–12% to equipment costs. (ABC Machinery provides online installation guidance, if you buy a large flour production line, we will send engineers to help you install it.)For example, a fully automatic 150-ton/day setup may require USD 400,000–550,000 for machinery and installation.

From Small to Large Flour Mill Plant for Sale at Low Price

Wheat accounts for 65–70% of operational expenses. Purchasing 1,000 metric tons of wheat at USD 320–350 per ton means allocating USD 320,000–350,000 as initial stock. Additional working capital of USD 50,000–100,000 covers packaging, utilities, and payroll for the first 2–3 months.

Table: Estimated Cost Breakdown For Mid-Capacity Plant (150 Tons/Day)

| Cost Component | Estimated Range (USD) |

|---|---|

| Land Acquisition | 100,000 – 900,000 |

| Building Construction | 625,000 – 875,000 |

| Machinery & Install. | 400,000 – 550,000 |

| Initial Wheat Stock | 320,000 – 350,000 |

| Working Capital | 50,000 – 100,000 |

Long-term savings often outweigh initial investment when focusing on energy efficiency and workflow automation.

Choosing the right combination of land location, equipment capacity, and operational planning can reduce the payback period by 1–2 years. Industrial zones with government tax incentives can save up to 10% on annual operating costs.

Get Your Customized Flour Mill Plant Cost Analysis – Contact Our Engineering Team Today!

Efficient flour mill plant layout design directly impacts energy usage, production output, and maintenance access. A well-structured layout can raise productivity by 15–25% and cut material handling time by up to 30%.

An optimized wheat milling process includes receiving, cleaning, tempering, grinding, sifting, and packaging. Placing related operations adjacently minimizes conveyor length and ensures smooth flow.

For a 150-ton/day facility, a 2,500–3,000 square-meter building allows sufficient space for equipment, wheat storage, and finished goods staging. Integrating automatic flour mill machines can reduce manpower from 25–30 workers down to 15–18. Designing for scalability ensures capacity expansion by 20–30% without major reconstruction. Optimizing airflow and dust control systems not only improves flour quality but also extends equipment life by 15–20% through reduced wear.

Wheat Flour Mill Process Steps and Machines

Grain Mills Profitability, Cash Flow, And Payback Period Analysis in Pakistan

Profit margins in Pakistan’s wheat flour market generally range from 8–12% for standard flour and up to 15% for specialty fortified flour. For a 150-ton/day plant, monthly gross profit can reach USD 45,000–70,000 depending on wheat prices and market demand.

Cash flow stability is essential for managing seasonal price fluctuations in wheat procurement. A thorough flour mill plant profitability analysis indicates a payback period of 3–5 years, with ROI improving to 25% annually after debt repayment.